Titanium Sponge System

The operational system consists of a 13-ton of Titanium Sponge Reactor, an 1800-ton Hydraulic Press and the latest Russian Titanium Sponge Crushing technology. This production line controls every step of the process, including: chlorination, electrolyzation, reduction & distillation, to ensure production of high quality Titanium sponge.

Smelting System

We invested to ensure that our smelting production system is world class. The overall system consists of two 3-ton Vacuum Arc Remelting (VAR) furnaces and four 10-ton VAR furnaces, a high-precision automatic titanium sponge mixing system from America and an 8,000-ton hydraulic press.This gives us capability to produce ingots up to 12-tons and an operational capacity of 15,000 tons per year.

Forging System

The operational capacity for Titanium and alloy billet, bar, disc, ring and forgings is 15,000 tons per year. The production equipment to do this includes our 4,500-ton high-speed forging press, which operates up to a maximum of 110 strokes per minute and is controlled By Siemens' SIMATIC Programmable Logic Control and data-logging system.To ensure a stable process and high-quality output, the system also comes with infrared automatic temperature detection and omni-directional cameras, which can monitor the whole process while the forging press is in operation.

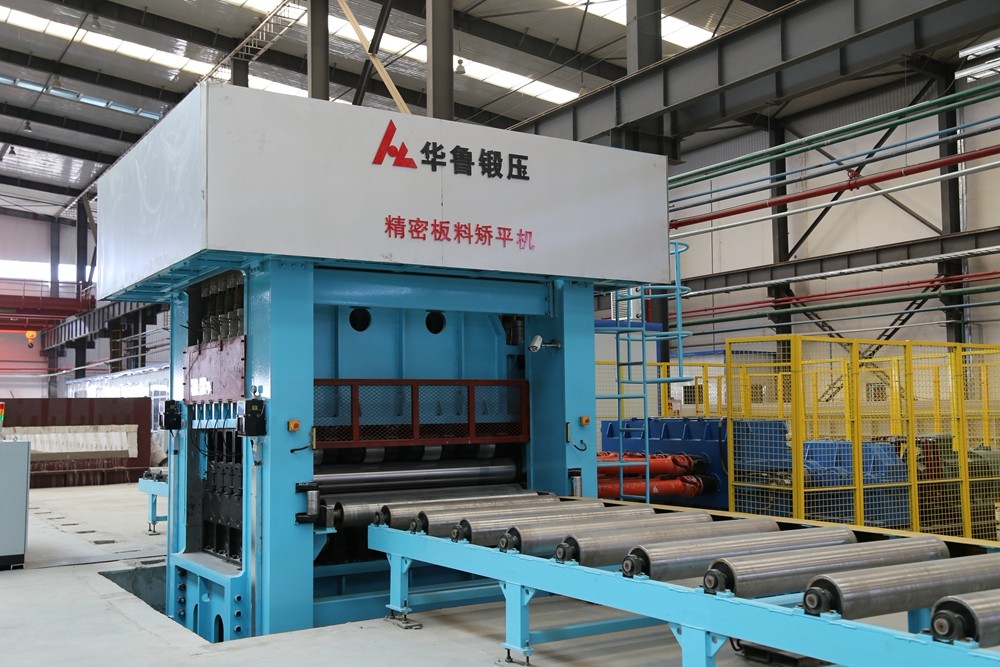

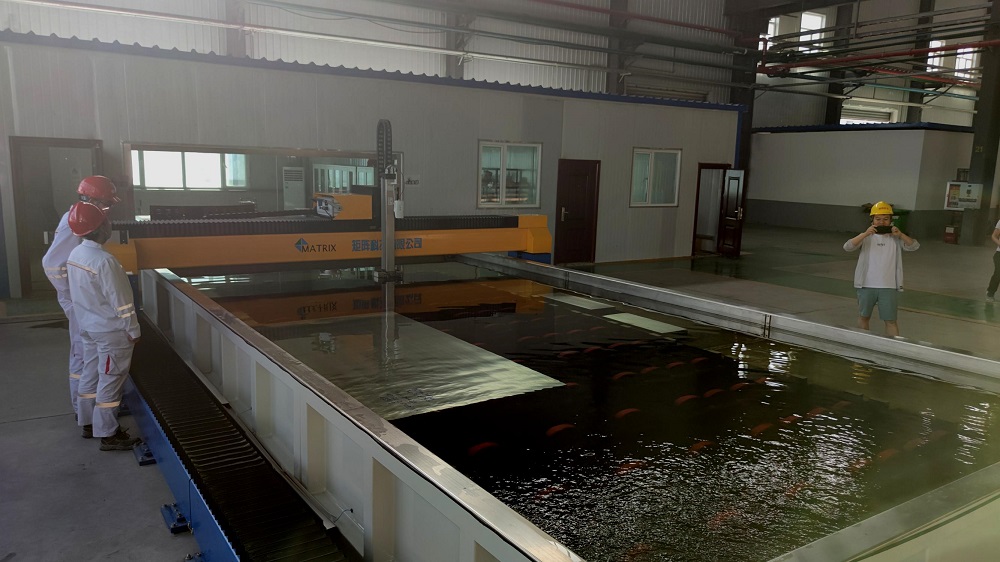

Sheet & Plate Production System

Our production capacity for Titanium and alloy sheets, plates, coils and strips is 20,000 tons per year. The production line includes a 2.45M 4Hi Reversible Rolling Mill, an Electric Heating Furnace, a Vacuum Creep Flattening machine, a Hot Flattening machine, a Sheet Flattening machine, a Pickling line, a Shearing machine, a Water jet cutting machine, a Grinding machine, a Flame-cutting machine and a shot blasting machine. Our 2.45M 4Hi Reversible Rolling Mill has a maximum material input of 550mm and can achieve output plates down to 100mm thickness and 2200mm width. A single pass can reduce thickness by up to 40mm. The quality of our finished products is closely monitored for both metallurgical stability and dimensional consistency.

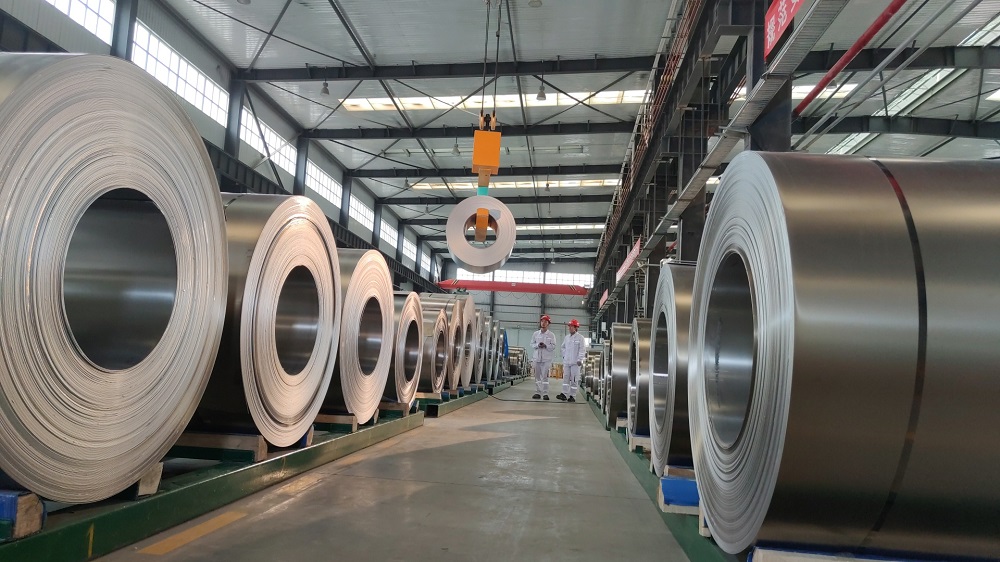

Coil/Strip & Clad Coil System

We produce clad coil, strips and sheets at our Hami site, using a 1.45M 4Hi Reversible Clad Coil Rolling Mill, a Flattening line, a Slitting machine and a Vacuum Annealing Furnace. We are capable of producing both hot and cold rolled coils and strips at a variety of standards and grades, including: TA1(Gr.1), TA2(Gr.2), TA3(Gr.3), TA4(Gr.4) and TA10(Gr.12). Our current operational capacity per year is: 10,000 tons of titanium strip, 10,000 tons of clad coil and 2 million pieces of titanium alloy discs.